The axe handle is a crucial component of the axe, as important as the head itself. It’s not just a means to hold the tool; it’s what transfers the user’s force to the axe head and ultimately to the chopping surface. This comprehensive guide will delve into the intricate details and definitions associated with axe handles, enhancing your understanding and helping you make informed decisions.

Understanding the Importance of an Axe Handle

A good axe handle absorbs shock, provides comfort, and ensures safety during use. It can greatly affect your accuracy, efficiency, and endurance in tasks like chopping, splitting, or shaping wood.

Types of Axe Handles

1. Wooden Handles

- Common Woods: Hickory, ash, and maple are popular choices for their strength and shock-absorbing properties.

- Pros: Good shock absorption, traditional feel, and can be replaced or customized.

- Cons: Susceptible to weather, can break or splinter over time.

2. Fiberglass Handles

- Description: Made from fiberglass composites, often with a core of wood or other materials for added strength.

- Pros: Weather-resistant, low maintenance, and more durable than wood.

- Cons: Less shock absorption compared to wood, can be difficult to replace.

3. Steel Handles

- Description: Made entirely of steel, usually with a rubber grip for comfort.

- Pros: Extremely durable and resistant to weather and wear.

- Cons: Heavy, can cause more fatigue, and lacks shock absorption.

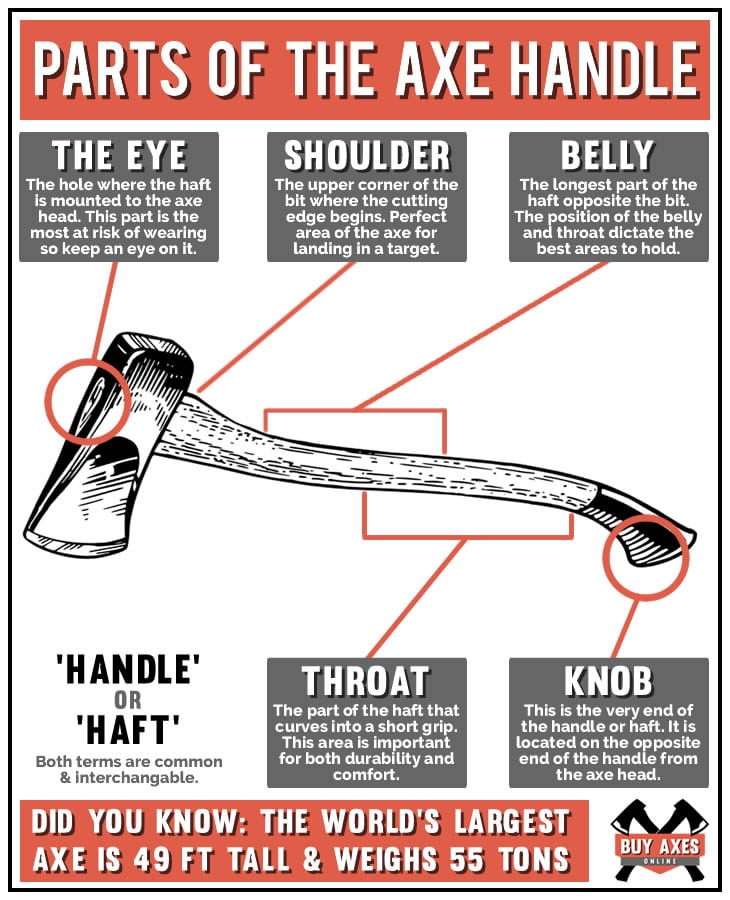

Anatomy of an Axe Handle

- Grip: The part of the handle you hold. It can be bare wood, rubber-coated, or wrapped for comfort and grip.

- Shoulder: Where the handle widens to meet the axe head.

- Belly: The curved part of the handle, providing grip and leverage.

- Throat: The narrowest part of the handle, just above the grip.

- End Knob or Swell Knob: The base of the handle, preventing the axe from slipping out of your hand.

Handle Length and its Impact

- Long Handles: Provide more power and swing speed, ideal for felling and splitting. Usually 30 inches or longer.

- Short Handles: Offer more control and precision, suitable for carving and detailed work. Typically around 14 to 20 inches.

Handle Shapes

1. Straight Handles

- Use: Common in splitting axes and some chopping axes.

- Advantages: Easier to manufacture and replace, offers consistent alignment.

2. Curved Handles

- Use: Often found in felling axes.

- Advantages: Ergonomic, allows for a more natural swing and can reduce fatigue.

Choosing the Right Handle

Consider these factors when selecting an axe handle:

- Task: Match the handle to your intended use – longer for felling, shorter for carving.

- Material: Choose based on durability, weight preference, and shock absorption.

- Comfort: The handle should feel comfortable and natural in your hands.

- Balance: A well-balanced axe will feel like an extension of your arm, improving efficiency and reducing strain.

Handle Maintenance

1. Wooden Handles

- Oil Regularly: Use linseed oil or similar to keep the wood from drying out and cracking.

- Storage: Keep in a dry place to prevent warping or rotting.

- Inspection: Check for cracks or splinters and sand or replace if necessary.

2. Fiberglass and Steel Handles

- Inspection: Check for any signs of wear, cracks, or damage.

- Grip Maintenance: Replace grip tape or rubber as needed for comfort and safety.

Replacing an Axe Handle

Sometimes an axe handle needs to be replaced, whether due to damage or wear. Here’s a brief overview of the process:

- Remove the Old Handle: Cut off the old handle and drill out the wood inside the axe head.

- Select the New Handle: Choose the right type and size.

- Fit the Handle: Insert the new handle into the axe head. It should fit snugly.

- Secure the Handle: Use a wooden or metal wedge to secure the handle in place.

- Trim and Finish: Trim any excess handle protruding from the head and sand if necessary.

Customizing Axe Handles

Customizing your axe handle can improve comfort, efficiency, and personalization:

- Sanding for Grip: Sanding the handle can improve grip and comfort.

- Adding a Grip: Wrapping the handle with leather or rubber can provide additional comfort and reduce slippage.

- Painting or Staining: For personalization and protection.

Axe Handle Safety

A damaged or poorly designed handle can be a safety hazard:

- Regular Checks: Regularly inspect your handle for damage.

- Correct Usage: Use the axe as intended to prevent undue stress on the handle.

- Proper Storage: Store properly to avoid environmental damage.

Conclusion

The axe handle is a critical component that significantly influences the functionality and safety of the axe. Whether you prefer the traditional feel of wood, the durability of fiberglass, or the strength of steel, understanding the details and definitions associated with axe handles is essential. A well-chosen and well-maintained handle will not only enhance your axe-wielding experience but also ensure longevity and safety in your tasks. Remember, the best axe handle is one that feels right in your hands and suits the specific demands of your work or hobby.